-

If you have a small or desktop laser cutter or a low-power laser engraver,

But need to make thick material cutting or get faster cutting speed,

Then the best choice is to upgrade your laser cutting machine to higher power by yourself

To upgrade the laser machine to a higher power, the first laser parts you need to upgrade is the laser tube

Commonly different laser tube power has different length,

One can already give output higher laser power, following is the popular specification for co2 laser tube

Tube Model Rated power Peak power Length of laser tube Diameter of laser tube C50 50w 70w 1000mm 50mm C60 60W 80w 1200mm 50mm C80 80w 110w 1600mm 60mm C90 80w 100W 1250mm 80mm CS100 95W 115w 1350mm 80mm C100 100W 120W 1450mm 80mm C130 130w 150W 1650mm 80mm C150 150W 180w 1850mm 80mm NOTE: Different manufacturer produces laser tube with low power of different peak and lengths

The second parts of the laser need to be updated is the power supply of the CO2 laser (PSU laser)

Higher power laser tube with higher temperature inside, need industrial water chiller with compressor for cooling

Commonly 80w laser tube or less, the CW3000 cooler without compressor will be fine. But if it improves to 100w, 130w, 150w laser tube,

Then chiller with compressor will be neccessary like CW5000 or CW5200 (for double laser machine cutting head)

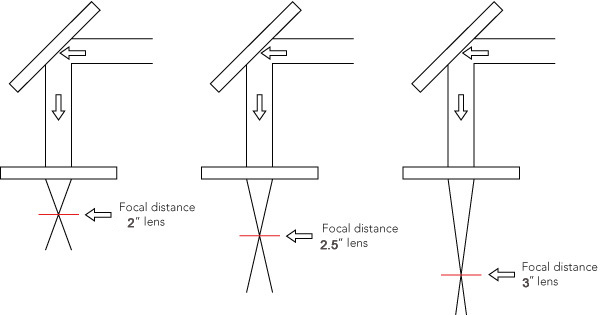

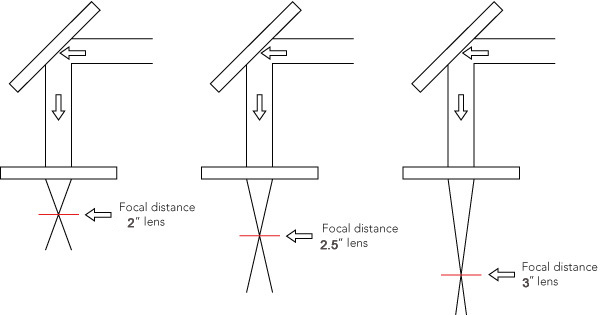

If you would like to cut thicker materials such as acrylic or wood/mdf, you should check the focal length of your current focus lens

Commonly lenss that the material of 10mm thickness, 1.5 ", 2" and 2.5 "focal length lens will be suitable,

But for cuting10-20mm materials, then 2.5 ", 3" or 4 "focal length lens will be necessary.

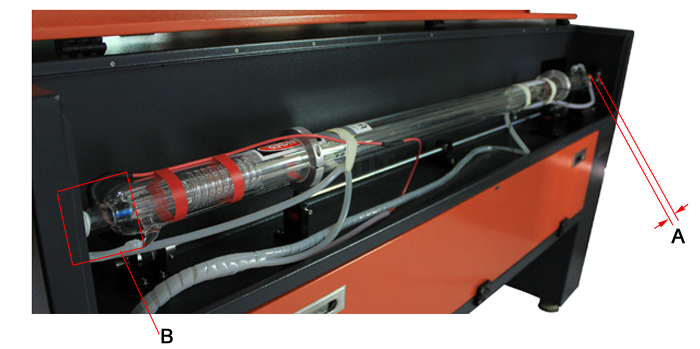

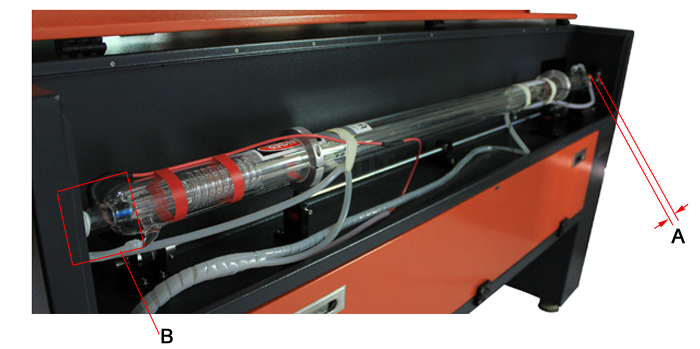

When you upgrade the laser cutter to a higher power, these 2 sizes should be checked twice as shown below:

Size "A" is the distance between the laser tube exit window and the first mirror, it should be> = 5cm

Size "B" is the high voltage end of the laser tube, the distance between the laser tube to the machine body

In each directionMust be> = 10cm to avoid the risk of high voltage discharge

The other thing that should be considered for the update of the laser is the new length of the laser tube

TThe best option is to choose new laser tube shorter than the machine body,Which is it can be put inside and installed well

If the necessary laser tube is longer than the machine body, then the solution for you is

Extend machine body with extended coverAs a photo above to fix and protect the laser tube.

info@fivelaser.com

info@fivelaser.com